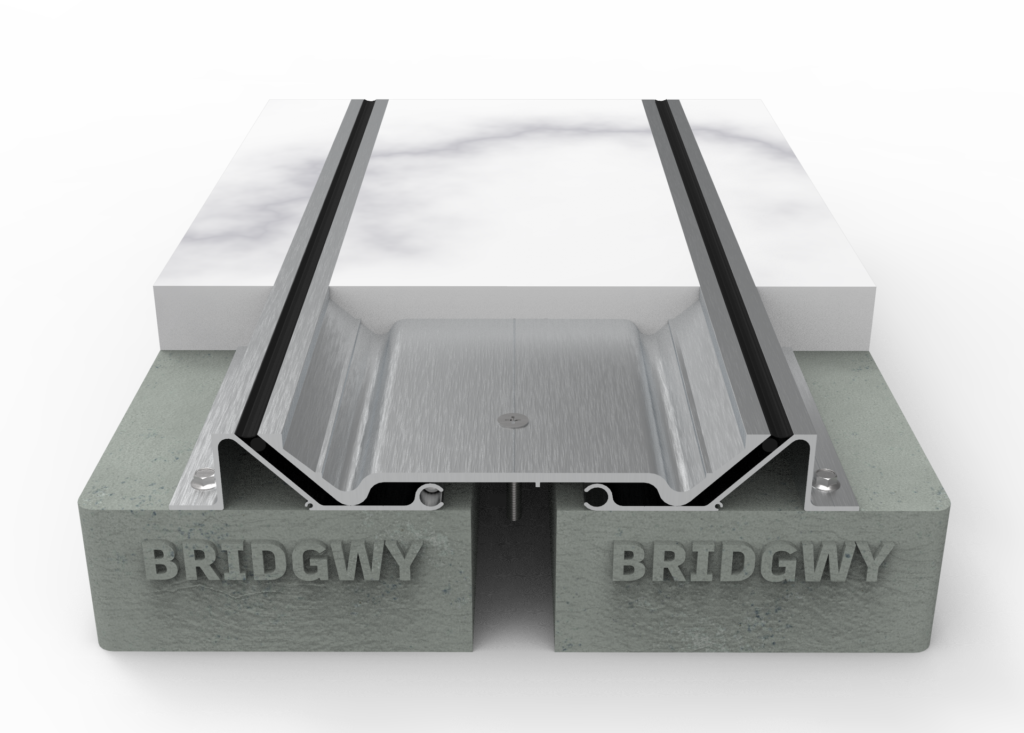

Pan-type expansion joint covers are specialized components used in construction and architectural projects to accommodate movement between different sections of a structure. These covers are particularly useful in bridges, highways, buildings, and other structures where there may be thermal expansion, contraction, or other forms of movement that need to be managed to prevent damage.

Key Features:

- Movement Accommodation: They are designed to handle the expansion and contraction of building materials, ensuring that structural integrity is maintained.

- Durability: Typically made from robust materials such as aluminum, steel, or other durable metals to withstand various environmental conditions.

- Aesthetic Integration: These covers can be designed to blend seamlessly with the surrounding surfaces, maintaining the visual appeal of the structure.

- Waterproofing: Many pan-type expansion joint covers include features that prevent water ingress, protecting the underlying structural components from moisture damage.

- Ease of Installation: Designed for easy installation and maintenance, often requiring minimal tools and expertise.

Applications:

- Bridges: To handle the significant movement caused by traffic loads, temperature changes, and other factors.

- Buildings: To accommodate the differential movement between different parts of a building, such as between floors or sections.

- Highways and Pavements: To manage the expansion and contraction of concrete or asphalt surfaces due to temperature changes.

Types:

- Surface-mounted Covers: These are installed on the surface of the joint and are visible.

- Recessed Covers: Installed within a recess, these covers are flush with the surface and are less visible.

Maintenance:

Regular inspections and maintenance are crucial to ensure the longevity and functionality of pan-type expansion joint covers. This includes checking for any signs of wear, corrosion, or damage and ensuring that the covers are clean and free from debris that might impede their movement.